AF ENGINEERING

Engineering services in plant and mechanical engineering

Design, technical project management and consulting in general mechanical engineering and special machine construction

Tailor-made products and services for your project, individual designs, development and calculation of fixtures and machines

Services

Specialization in riveting technology

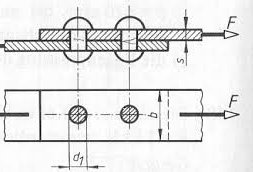

The riveted joint is an undetachable connection and is assigned to the form-fitting connections. The plastic deformation of the rivet heads (with solid rivets) ensures the undetachable connection.

As a rule, solid rivets with a rivet diameter a=10mm are pressed or struck in the hot state.

When it cools down, the shaft shrinks, wich builds up a tensile force on the components.

Setting tools:

- Riveting hammer

- Counterholder

- Hydraulic press

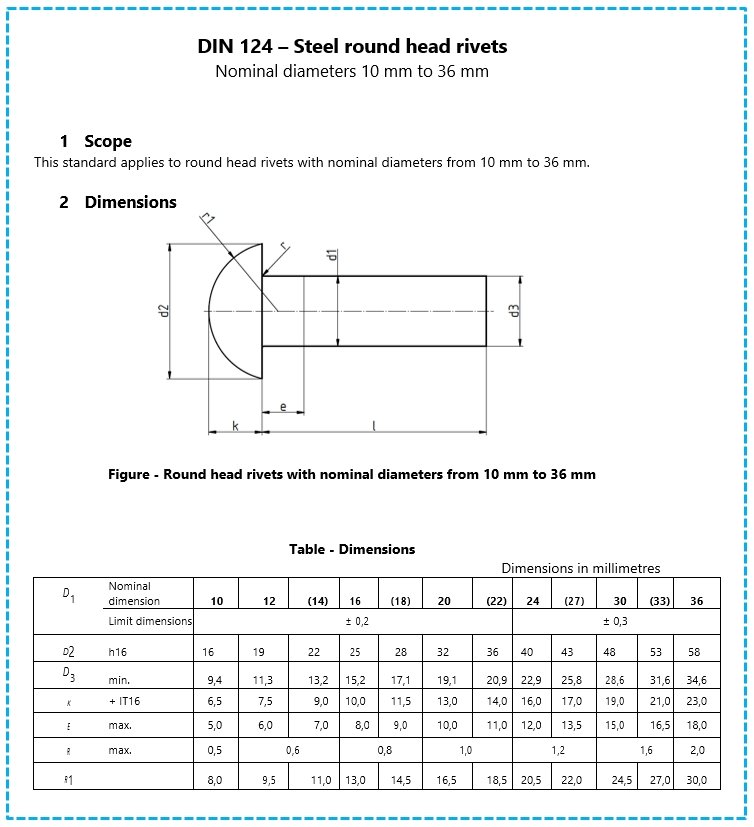

- Round head rivets DIN 660 or DIN 124

New construction based on the original drawings of water tanks, coal tanks, driver's cabs and smoke boxes of steam locomotives

We offer:

-

Precise dimensional accuracy in accordance with the standards "German engineering standards" (DIN 7168- m / DIN ISO 2768-1)

-

Perfect finish thanks to the use of modern production technologies (3D-CAD; numerically controlled sheet metal cutting and rivet hole insertion, etc.)

-

Use of the most modern tools and specific training of the workers in order to ensure the best possible joint quality (i.e.: of the rivets) and the best possible finish (absolutely straight rows of rivets, perfect (better than original!) rivet spacing, no dents etc).

-

Favourable price / acceptable delivery time.

Projects

Riveting technology

The fascination for the steam locomotives brought riveting technology into the agenda of the AF Engineering Team, to put it on a professional basis. The riveting technique, which underlines the originality and authenticity of several renovated steam locomotives, is hardly used nowadays due to high costs and lack of know-how.

Background is the fact that in Western Europe hardly anybody seems to master the technology of "hot riveting" (right !) and/or this production technology is almost unaffordable here. Anyway, most of the otherwise well restored museum locomotives with completely curved / crooked / dented / patchy and no longer original (as delivered !) water and coal tanks, cabs and smoke chambers look rather shabby.

Welded water and coal boxes are ALWAYS deformed due to the manufacturing process, which is generally not the case with riveted versions.

Prototype

A simple box was constructed and assembled using the rivet joint.

- Drawing a sketch

- Construction

-

Laser cutting of sheet metal pieces and angle profiles

-

Cutting the rivets to the right length

-

Preheating the rivets

- Riveting

-

Hydraulic press

-

Jackhammer

-

As a prototype a part of the water tank of the BR 80 with a width of 410mm was manufactured. Despite the narrow interior, it could be shown that the accessibility of a press or a pneumatic hammer is still possible despite the tight installation space.

Water tank BR 80

The water tank of the class 80 steam locomotive was redesigned based on the original drawings.

A complete engineering activity (redesign of the water box) of the steam locomotive series BR 80 was performed in 3D-CAD. See the following pictures.